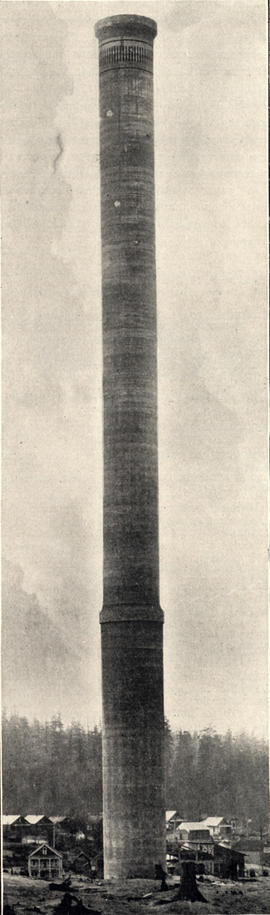

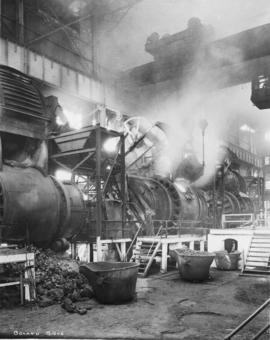

On October 27, 1948, Permanente Metal Corporation employees, left to right, Charlotte Thorestad, C.P. (Pat) Love (plant manager) and Darlene O'Brien sat surrounded by a sea of iced cupcakes marked with a "P" and decorated with a single candle. Permanente's aluminum reduction plant at 2400 Taylor Way was celebrating its first year of production of Kaiser Aluminum with a "Family Day" Open House. Employees along with 1,500 friends, families and relations were the guests of management. They observed the step by step process of making aluminum and ate hot dogs cooked on a 500 lb. "pig" of aluminum, sandwiches, cupcakes and punch. The plant had been previously operated during World War II by the Olin Corporation. After its purchase by Kaiser, it became one of six aluminum plants operated by the company. The other plants were located at Mead and Trentwood Washington (near Spokane), Baton Rouge La., Newark Ohio and San Jose Ca. The Tacoma plant was permanently closed in 2002 and later demolished. (TNT 10/28/1948, p.1)

Permanente Metals Corp. (Tacoma)--Employees; Aluminum industry--Tacoma--1940-1950; Employees--Tacoma--1940-1950; Baked products--Tacoma--1940-1950; Love, Charles P.; O'Brien, Darlene; Thorestad, Charlotte; Anniversaries--Tacoma--1940-1950;