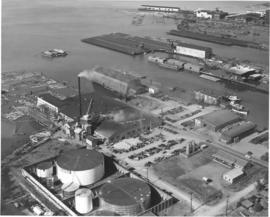

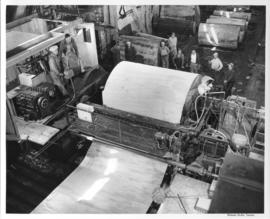

Back of Photo:

"St. Regis - Western Star Paper Machine

Clipping taped to back: "READ ALL ABOUT IT--Seven St. Regis Paper Co. officials, her for this morning's official dedication of the company's $30,000,000 expansion of its Tacoma kraft pulp and paper mill, look over a special 18-page section of The News Tribune, marking the event. Seated, left to right, are Phillip B. Duffy, vice president, the corrugated container division; Reginald L. Vayo, vice president, kraft division sales; and Kenneth D. Lozier, vice president, of advertising and sales promotion, all of New York. Standing are George J. Kneeland, New York, assistant vice president; Russell R. Major, Tacoma, assistant comptroller; John A. McDermott, Jacksonville, Fla., vice president, pulp and paper manufacturing; and Dr. William R. Haselton, general manager of the Tacoma plant."