- Item

- 1948-01-29

Part of Richards Studio Photographs

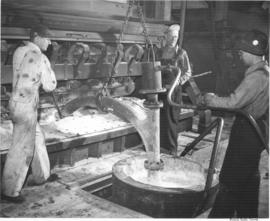

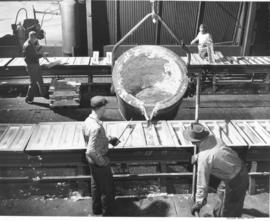

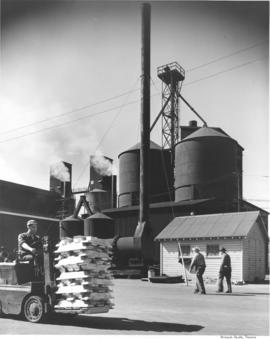

Permanente. The white, powdery alumina was discharged from bins into electrolytic cells known as reduction pots where it was periodically stirred. After heating in the reduction pots the molten aluminum was siphoned from the pots into 1 1/2 ton ladles. The ladles would be transferred by crane to the end of the potroom buildings where the molten metal was poured into molds forming pigs weighing 50 to 1,000 pounds. (Permanente Metals Corporation 1947-1948 Annual Report) TPL-4541

Permanente Metals Corp. (Tacoma)--Employees; Aluminum industry--Tacoma--1940-1950; Aluminum; Laborers--Tacoma--1940-1950; Founding--Tacoma--1940-1950; Foundries--Tacoma--1940-1950;