- Item

- 1935-09

Part of Richards Studio Photographs

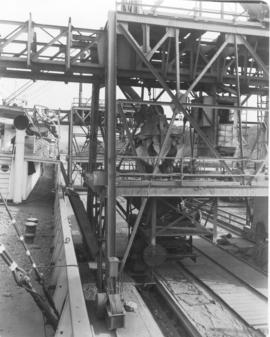

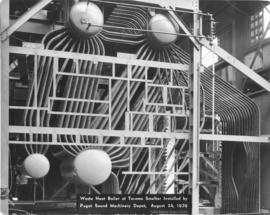

This is the American Smelting & Refining Company smokestack in Ruston as pictured in September of 1935. At 571 feet, the ASARCO smokestack dominated the skyline near Point Defiance from its elevated position above the waterfront. At the time of its construction in 1917, it was the tallest smokestack in the world. It lost nine feet in height after repairs in 1937. The smelter stack was demolished on January 17, 1993.

American Smelting & Refining Co. (Tacoma); Smelters--Tacoma--1930-1940; Copper industry--Tacoma--1930-1940; Industrial facilities--Tacoma; Smokestacks--Tacoma;