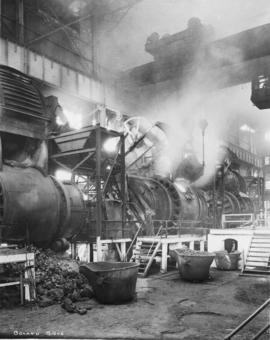

- Item

- 1906

Part of General Photograph Collection

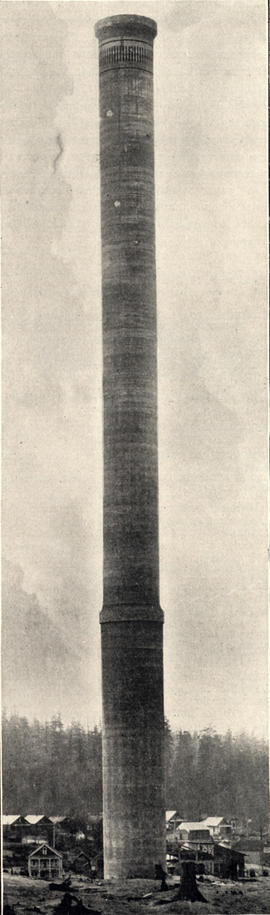

ca. 1906. Tacoma smelter smokestack. At the time of its completion in 1905, this was the largest concrete chimney in the world. It was located on the grounds of the American Smelting & Refining Co. (ASARCO) plant in Ruston. It would be superceded by the 571-foot smokestack completed in 1917. (Tacoma New Herald Annual NWR 917.97 T119N 1906)

American Smelting & Refining Co. (Tacoma); Smelters--Tacoma; Industrial facilities--Tacoma; Smokestacks--Tacoma;